extruder

.

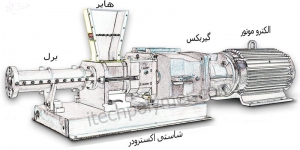

The extruders produced by this company are in two general sizes

-

Industrial extruder

-

Laboratory extruder

Extruder types

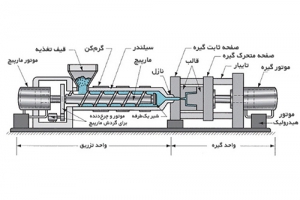

Conventional extruders are generally divided into single-screw and double-screw categories. Of course, they can be separated in another package in terms of feed temperature (raw material), which we will explain in the following.

1) Single-screw extruders

One of the most common methods of forming plastics is extrusion, which consists of a mardon. The single-screw model is one of the types of extruders that is able to perform the material extrusion process, without tolerance, so that it is able to optimize material and energy consumption at the same time. Other features of this device include long life, high production capacity and optimal product quality.

Working method of single-screw extruder

The raw materials of this device are introduced into the mortar from the funnel in the form of granules or soft soil. حال این مواد در اثر حرارت حاصل از گرم کننده های دستگاه (Barrel Heaters) و برش ناشی از حرکت بر روی لبههای ماردون گرم میشود. , Then the depth of the passage decreases along the mardon and causes the material to compress. At the end of this machine, the molten material is shaped to the desired product by passing through various molds. Single screw extruders are mainly used for the production of polyethylene pipes.

One-screw extruder feature

One of the important features of extruders is the ratio of length to diameter (L/D) in them. The output of this machine is directly related to the ratio of length to diameter (L/D); For example, two extruders with the same diameter but different (L/D) have very different outputs.

Taller extruders have greater melting and mixing capacity, and also allow the machine to move faster. In principle, a larger diameter extruder will have a higher output rate accordingly, so single-screw extruders usually have a faster output speed than double-screw extruders, but their homogenization power is lower. For this reason, it is usually better to use two consecutive extruders in the lines that use this type of extruder, so that the former performs the process of mixing and homogenization and the latter performs the extrusion process.

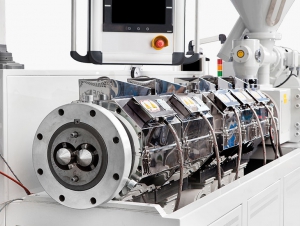

2) Two-screw extruders

Another type of extruder is a double-screw extruder. This device is commonly known as the twin screw extruder, but the dimensions of these screws are not necessarily the same. Some of these devices use Mardons to move in two opposite directions and others in one direction, and in addition Mardons may be in conjugated or non-conjugated form. The production capacity of two-screw extruders is usually three times that of single-screw extruders with the same diameter and speed, and they will be able to produce 6 tons per hour.

In recent years, the use of two-screw extruders has increased. Compared to single-screw extruders, this device has a different output rate, mixing efficiency and heat produced.

How to work double screw extruder

In a two-screwextruder with the opposite direction of rotation, the material is cut and compressed (as is the case with rollers), ie the material is compressed between rollers with different rotational directions.

In the same direction of rotation, the material is transferred from one mardon to another mardon. This device is quite suitable for heat-sensitive materials, because the materials in this type of machine are transferred quickly without the slightest local deposition (entrapment) for the material, and on the other hand, the movement of the material around the unpaired mardons is slower and Its propulsive force is greater.

Advantages of double screw extruders

- Compared to a simple Mardon, which must be full of raw material to operate, the amount of raw material entering the extruder of the two Mardons can be adjusted independently of the amount of raw material input and fluctuations in the amount of production inside the Mardon.

- Double-coil machines can move high-humidity materials or other products that slip in the single-coil type and are not well transported, in fact, these machines have more flexibility in production.

- In this type of device, moving the device forward or backward is used to control the pressure in the tank.

- In the low discharge section, the necessary pressure for extrusion operation is provided and provided to the smaller part of the device.

Extruder application:

Extruder products can be divided into 6 main groups depending on the type of application they want:

- Pipes and profiles

- Pipe

- Film and sheets

- Single strings

- Extrusion coatings

- Wire and cable cover

Extruder shell or body:

It is a metal cylinder that surrounds the helix. Inside this cylinder, holes are installed so that hot and cold water can pass and control the temperature of the extruder. If the temperature of the mixture is not controlled, the mixture becomes hot, which causes the output product to be roasted or burnt out (or originally to be scorched).

| Type | Single screw | Round alignment of low speed | Round high speed alignment | Round inconsistent |

| Transmission efficiency | low | medium | medium | high |

| Mixing efficiency | low | Medium and high | Medium and high | high |

| Cutting action | high | medium | high | low |

| Self-cleaning | modest | Medium and high | high | high |

| Energy efficiency | low | Medium and high | Medium and high | high |

|

Thermal distribution |

wide | medium | narrow | narrow |

| Maximum spin speed | 300-100 | 35-25 | 300-250 | 45-35 |

| Maximum L/D ratio | 32-30 | 28-7 | 40-30 | 21-10 |

Spiral:

In a cold-fed extruder, as the name implies, the rubber compound is fed at room temperature. The feed may be in the form of strips or grains. The spiral must transfer sufficient mechanical energy to both soften the mixture and withstand the back pressure of the die.

Special considerations are required in the design of coils used in cold-fed extruders. In order for the mastication to be done in the required amount, the height of the helix blade must be low and the helix length must be high.

The screw of a simple extruder has three parts of feeding, transfer or measuring part and compression part. Each helical part has a separate role. The feed section transfers the material from the feed hopper. The transfer section heats and mixes the material.

The compression part is uniform and the necessary pressure to drive the material out of the die is created in it.

There is also a temperature control inside the helix. Inside the spiral are adventures through which water can pass to control the temperature. The speed of the helix has a great effect on the temperature of the extruder.

Ideal speed for spiral extruders:

It is the speed limit that can receive the rubber from the feed and prevent it from accumulating in the feed funnel.

Head:

The purpose is to balance the pressure and transfer the mixture to the mold.

The shape of the head should be designed to meet the necessary needs:

- Provide maximum output product without any problems and disorder

- Deformation compensation due to the elastic return properties of the compound

- Eliminate stationary and static areas that are likely to be created in the mixing path.

Template :

The mold is a body that is placed on the head (head) and causes the mixture to take the shape we want when it comes out. In general, designing a die requires a lot of skill and experience.

L/D ratio in plastic extruder:

L/D or the ratio of the length of the screw to the outer diameter of the screw is one of the most important ratios in the design of the extruder, which can usually be increased up to 34. In ordinary extruders this ratio is usually 24. In ordinary extruders this ratio is usually 24.

| The benefits of shorter extruders | The benefits of a long extruder |

| Land area less | More and better mixing ability |

| lower price | Pump pressure to higher temperatures |

| Less torque due to smaller engine with less horsepower | Appropriate melting capacity with lower heat |

| The heat transferred from the electricity by conduction is greater |

It is necessary to explain and note that among the manufacturers of the device in Iran, only 2 or 3 units have a license and exploitation license for industrial and mining structures. Behsaz Polymer Industrial Group has been operating under the license of the Industrial Organization since 2000.

And also, unfortunately, most advertisers on the Internet are intermediaries as manufacturers of disposable tableware and do not have any license from the Department of Industry and even choose the name of the company or brand to introduce their product is not registered in any office or organization.

Any copying of the contents of the site without including the source will be prosecuted.

We hope thesa content was helpful

Behsaz Polymer Industrial Group

Laboratory Extruder Machine قیمت دستگاه اکسترودر آزمایشگاهی فروش دستگاه اکسترودر آزمایشگاهی خرید دستگاه اکسترودر آزمایشگاهی تولید دستگاه اکسترودر آزمایشگاهی تولید کننده دستگاه اکسترودر آزمایشگاهی کارخانه دستگاه اکسترودر آزمایشگاهی تولید کنندگان دستگاه اکسترودر آزمایشگاهی فروشنده دستگاه اکسترودر آزمایشگاهی فروشندگان دستگاه اکسترودر آزمایشگاهی صادرات دستگاه اکسترودر آزمایشگاهی فروش عمده دستگاه اکسترودر آزمایشگاهی قیمت عمده دستگاه اکسترودر آزمایشگاهی مرکز فروش دستگاه اکسترودر آزمایشگاهی ساخت دستگاه اکسترودرآزمایشگاهیسازنده دستگاه اکسترودر آزمایشگاهی واردات دستگاه اکسترودر آزمایشگاهی وارد کننده دستگاه اکسترودر آزمایشگاهی دستگاه اکسترودر ورق Laboratory Extruder Machines

/editor/TTT.png)