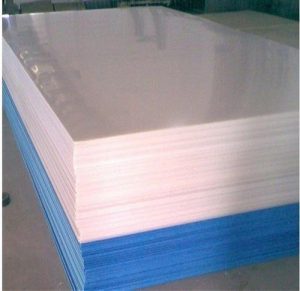

PP / polypropylene sheet

Expanded polypropylene, or PP, is a bubble or layer of polypropylene that has good compressive properties due to its low stiffness and allows it to return to its original state after application, and is widely used in the aviation industry and Radio control devices are used, which is due to the ability to absorb pressure.

The name of this product is polypropylene (PP) and its chemical formula is [CH2-CH (CH3)] n–. Polypropylene is one of the most widely used and basic polymers used in the world and the largest consumer of propylene.

Polypropylene The polymerization of propylene is performed under relatively mild temperatures and pressures in the presence of the famous Ziegler-Nata catalyst. The presence of this catalyst forms an isotactic polymer that is able to crystallize up to about 90%.

Polypropylene or PP is a thermoplastic polymer that is used in a wide range of applications including film and sheet, blow molding, injection molding, food packaging, textiles, laboratory and medical equipment, pipes, industrial and construction applications, and automotive components. In addition, polymers made from propylene monomer are typically resistant to chemical solvents, bases, and acids. The characteristic code of this polymer is.

PP or polypropylene sheet is one of the types of plastic sheets, the cost of production and raw materials such as PE polyethylene sheets are low. PP polypropylene sheets are produced by polymerization of propylene gas. PP sheets are low density semi-crystalline polymer polypropylene sheets, which makes polypropylene sheets have high resistance to heat and chemical changes and also has good mechanical properties.

Types of PP sheets

PP polypropylene sheets are produced in two types of copolymers and homo polymers, which have more properties than copolymer sheets. Now let’s look at the differences between the two.

Copolymer sheets have the ability to print, is also one of the clearest and most resistant to impact at high temperatures, another important feature of PP sheets is more mechanical properties and better glazing than Is a Homo polymer sheet.

PP sheet properties

These sheets are generally white. Commonly used thicknesses are around 020 to 2 mm. The dimensions of the sheets are generally 10 cm to 120 cm. The country of manufacture of these sheets is generally Iran.

Applications of PP sheet

- High impact at low temperatures

- High strength against abrasion and abrasion

- Resistant to electricity

- Non-toxic raw materials and produced

- Ability to weld

- Lighter than PET sheets

- Dimensional stability at high temperatures

- Ability to be laminated with PE polyethylene for insulation

- Higher transparency using additives

- Low price of PP compared to other polymers

- Specific weight and light PP

- Flexibility and wide range of PP production with variable physical and chemical properties

- Increase new applications and improve the properties of new production grades

- Increase the use of PP in medical devices and equipment and develop applications of special grade PP

- Increase the consumption of PP as an alloy with other polymers

- Replacement of polymers such as PS, PE, etc. with PP

Any copying of the contents of the site without including the source will be prosecuted.

We hope the above content was helpful

Behsaz Polymer Industrial Group