PLA disposable tableware production line

The production line of disposable vegetable dishes from ready-made raw materials of starch base has three stages and 3 main machines

First – granulation machine to produce raw materials with a combination of starch and other materials

Second – sheet and roll production machine prepared from raw materials

Third – Thermoforming press or vacuum forming machine for producing containers from ready-made sheets and rolls (produced in the second machine)

Introduction to each of the devices and their various components

The first device: Granulation Machine

The raw materials of disposable vegetable containers are a combination of starch, polymer and several additives that must be combined in a granulation machine.

In this machine, corn, wheat, potato, beet starch, etc. are combined with materials such as glycerin, PP polymer and other additives, and the raw materials are produced uniformly and in the form of granules.

Starch, polymer and other materials are first physically mixed in a high speed super mixer and at a certain temperature, and then in a granulation machine, these mixed materials are melted and combined together.

A – Super mixer device

B- Two-screw granulating machine with cooling of hot air material

Due to the specialization of the composition of materials in this machine, so friends who are working at the beginning is recommended to prepare raw materials from plant material production units and buy this machine to postpone this step to the next and the time of development of their production. To. Enough raw materials are being produced by other manufacturers who only produce granules.

Super mixer device

(For initial mixing of starch with polymeric materials and other additives)

Plant granule production machine with hot air

Cut granules with hot air

The second machine: the plant sheet production machine

As previously explained, the raw materials in the granulating machine are mixed with other materials and converted into sheets and rolls in the form of ready-made granules in this machine.

Of course, it should be noted that due to the fact that the production sheet is complete, so the produced sheet can be marketed as a final product.

In the second machine, ie thermo-forming sheet press produced in the sheet production machine, as the raw materials of this machine, it enters the press furnace part and after production and forming operations, the final product is produced in the form of disposable containers.

Extruder

In the plant sheet production machine, the raw materials, which are initially in the form of a mixture of granules and grinding materials, after entering, are melted and thoroughly mixed and removed from the extruder die head with high pressure in the form of non-uniform and uneven hot and paste sheets.

Cylinders and screws

with the element with a fan-shaped steel chamber, the extruder part of the plant sheet production line that provides the heat needed to melt the material, and the fans to prevent the elements from overheating the maximum heat tolerance of the material, because some materials with several degrees Rising above the maximum tolerable temperature of the material will cause discoloration as well as burns and changes in the properties and brittleness of the production sheet.

Lattice filter

of the extruder is a plant sheet production device that is installed between the Mardon cylinder and the extruder die head. The molten material is separated from other additional parts by passing the mesh filter inside it and the pure sheet easily passes through the mesh due to being molten and clean. The grid is also used with the power of the hydraulic jack. The filter also has two grids, one of which is always working and the second grid is outside and clean and ready to move inside the filter for work and the previous filter from the other side for Service and set up.

T-DIE head

T-DIE head of the extruder part of the sheet production machine, where the molten material enters the piece from the cylindrical shape into the sheet in an almost regular manner with a slow speed and slope, and at the output of this piece, a steel blade is adjustable. The extruder is adjusted with these blades.

Cylinder 90 cm wide with an angle of 60

Special for plant sheet production machine for use in the production of disposable vegetable containers

The Cylinder part of the machine, which is the output sheet of the extruder die head, which is irregular in thickness and width, in this part, the sheet is rolled and completely smoothed by passing between two steel rollers, and the thickness of the final product is adjusted between these rollers. From the third roller, which is cooled inside this roller, the sheet is almost cooled, but it is necessary to explain that the first and second rollers also have cooling and heating fluid, with the difference that it is cooled or heated at a higher temperature. The passing plate is not cooled before rolling in the passage distance between the two rollers, so as not to produce step-by-step sheet

Conveyor section

The conveyor part of the machine, where the rolled sheet is produced, is completely cooled by passing it gently over the rollers of this part, and at the output end of this part, two rubber and steel rollers control the driving force and movement of the sheet by adjusting the speed.

Electrical panel of sheet production machine

It is also necessary to explain that all the electric motors of the company’s production devices are equipped with an electronic speed inverter and are installed on the electrical panel.

General specifications of PP sheet production machine. PS High capacity BP-SH12PO model

Consumables PP. PS

Sheet thickness 0.2 mm 2.5 – mm

Sheet width 80-50 mm

Sheet production capacity 220 kg / h

Third machine: thermoforming press machine

The presses made by this company are intended for the production of disposable vegetable containers in 2 2 sizes, which are designed in the size and capacity of this Presses are based on maximum production efficiency using minimum energy consumption.

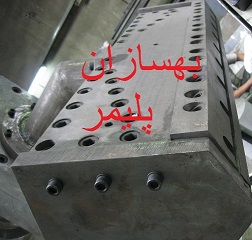

Plant-based thermoforming press

Thermoforming press mold seat page

General specifications of medium capacity thermoforming press

Consumable sheet materials

Sheet PP.PS.PET, PVC.

suitable Sheet Materials

Consumption sheet width

400-670mm

Sheet Width

Consumption sheet thickness

0.2-2.0mm

Sheet Thickness

Dimensions of press forming

300 × 630mm2

Max. forming Area

Maximum shaping depth

120mm

Max .cup depth

Forming wind pressure

0.5-0.8Mpa

Forming Pressure

Multiplication speed per minute

10-32 strokes / min

Productivity

Maximum power consumption

45kw / hour

Rated Heating Power

Device weight

4.5 (ton)

Total Weight

dimensions of the device

450 × 200 × 240 cm (L.W.H)

Overall Dimensions

Any copying of the contents of the site without including the source will be prosecuted.

We hope the above content was helpful

Behsaz Polymer Industrial Group