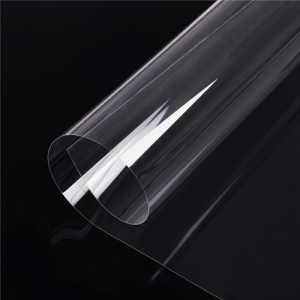

PET plastic sheet

PET plastic sheet or polyethylene terephthalate plastic sheet is a polymer used in the production of polyester fibers (70%), bottle resin (22%), film (6%) and engineering polyester resins (2%), but In Iran, this polymer is mostly used for making all kinds of beverage bottles and food packaging containers, electrical industries, pharmaceutical industries, and so on.

PET is prepared in two stages. The first step involves the reaction of terephthalic acid with 1-4 methane DL at 150 ° C to prepare dimer and trimer, which have two hydroxyl terminal groups. In the second step, PET is being formed by compression polymerization, and The mixture is heated to 260 ° C to a high degree of polymerization. Typically, low molecular weight materials (20,000 nm) are used to produce fibers, while for other uses, higher molecular masses are used.

Types of PET sheets

PET plastic sheets are usually available in the following two types:

Bottles: This type of PET is used to produce bottles, which determines the type of grade use of the bottle.

Fibers: This type of PET is also used in clothing and various types of PET films

Properties of PET plastic sheet

The order in the structure of the polymer chain increases the crystallinity, which is important for determining the mechanical properties. The phenyl group in the main chain hardens the skeleton and is responsible for the high Tg temperature and melting temperature. Its chemical resistance is like nylon hosts (polyamide) which makes it have very good impermeability properties.

PET can be present in both crystalline and amorphous states, and its degree of crystallization is determined by the thermal history of the material. PET fibers and thin films are produced by extrusion and cooling to ambient temperature. ͵ Due to the fact that the highest crystallization rate occurs at a temperature of about 170 ° C ͵ The degree of crystallization can also be done by annealing annealing between the melting temperature (Mt) and the glass transition temperature (Tg). -290 occurs.

The most volatile products are: terephthalic acid, acetaldehyde and carbon monoxide. At a temperature of 900 ° C, large amounts of hydrocarbons are produced along with carbon dioxide, carbon monoxide and methane, which are the main volatiles, and oxidation is possible during the process. A wide range of antioxidants can be used to prevent PET oxidation during the process.

Advantages and reasons of using PET plastic sheet

1- High speed vacuum thermoforming

2- Completely hygienic for food and medicine packaging compared to other polymers

3- Optimal mechanical properties

4- Good electrical properties (electrically insulated)

5- Suitable chemical resistance against acids, alcohols and salts

6- Relative resistance to climate erosion

7- Excellent toughness

8- High transparency in amorphous state

9- Full recyclability

10- No effect on the color and taste of food

11- Low permeability

Applications of PET plastic sheet

Due to the wide range of PET properties such as the ability to control the degree of crystallization ͵PET has found many applications. Its main application is in carbonated beverage bottles due to its high impermeability to gases in PET. For this purpose, amorphous PET is drawn in the direction of high Tg and in a directional direction to have a crystalline property. One problem with PET is that it tends to crystallize over time, which causes a change in properties and can lead to dimensional changes (shrinkage or warping).

Other uses of PET plastic sheet: Includes fibers for use in clothing, films made of PET plastic sheet, electrical insulation and parts produced by blow molding. In many applications, PET plastic sheet copolymer to achieve Use better properties.

Of course, the first use of recycled PET in the world and Iran: fibers, sheets and belts and injection or blowing products.

Short Tips on Recycling PET Plastic Sheets

PET can be recycled by almost all major recycling methods from mechanical to chemical, but mechanical recycling is more common. However, there are problems with recycling.

For example, labels attached to bottles can change color and reduce their transparency during recycling.

Or because of the sensitivity of this material to moisture, any residual moisture can lead to degradation, and degradation also causes yellowing and changes in mechanical properties. It has recently been shown that PET can also be recycled through pyrolysis, which produces activated carbon.

Tips on PET sheet recycling in Iran

Recycled PET plastic sheet requires high separation due to its sensitivity to PVC, although this must be observed in all PET recycling lines around the world. Polyethylene terephthalate plastic sheet In any case, to achieve high quality recycled sheet, you must use a hot wash line with a label separator.

Recycled PET sheet is the only plastic that has an index for the amount of pollution, which is called ppm, which stands for one unit per million. When we say PET sheet has 300 ppm of PVC. This indicator means that the amount of pollution in One ton of pet should be 300 grams.

This contamination in food applications, such as the production of bottles from recycled bottles or so-called bottle to bottle, should be below 10 ppm. For fiber applications it should be between 200-500 ppm. Naturally, the less pollution, the more valuable it is and the higher the price in the market.

Many people in Iran who own a pet recycling line and traditionally operate due to lack of facilities and equipment to separate the quality of the flake is not high and when selling it to fiber manufacturers suffers a large drop and reduces their profits. .

Last year, due to market fluctuations in the second half of the year, we saw a decline in the price and value of this plastic, but it is expected that in the new year, due to the liberalization of exports of recycled materials, the price of recycled PET will increase and the market will prosper.

Any copying of the contents of the site without including the source will be prosecuted.

We hope the above content was helpful

Behsaz Polymer Industrial Group