PP plastic disposable tableware production line (thermo forming model)

Disposable tableware production machines are generally in two types and production models

A. The first and almost old type of disposable tableware production line with PS semi-forming system

This model of container production line includes only one main machine and the raw materials in this machine are melted and converted into sheets and rolls and then converted into disposable containers.

This model of the machine has the ability to produce containers only from polystyrene (PS) and raw materials (glass or white but brittle containers)

B- The second type of disposable tableware production line with PP thermoforming system

Disposable tableware production line with PP thermoforming system

In this model, which is called a thermoforming press, disposable containers are produced from ready-made rolls and sheets.

Ready-made plastic sheets and rolls enter the machine and after heating in the heat furnace of the press machine, containers are produced in the mold part under wind pressure.

(In the previous model machine, which is called a semi-forming container production machine, unlike the thermoforming model, the raw materials enter the machine in the form of petrochemical granules and are converted into sheets and containers in the same machine)

Advantages and differences between semi-forming and thermoforming container production machine (new)

In the semi-forming machine, only PS polystyrene plastic containers can be produced, but in the thermoforming press machine, in addition to PS containers, PP polypropylene plastic containers can also be produced (PP containers are almost soft and do not break if the containers or glasses are crumpled. The one currently used for water and tea is PP)

The production circulation of thermoforming presses is about 2.5 to 3 times higher than semi-forming presses.

In the semi-forming machine, the raw materials are in the form of petrochemical granules, but in the thermoforming machine, the raw materials are in the form of rolls and sheets.

Thermoforming press machine

Thermoforming press ceramic element furnace

Furnace and thermoforming press mold

Sample of containers that can be produced with thermoforming press machine:

Circulation and production of different containers in PP thermoforming machine:

Production volume of 1 kg yogurt container is about 6000 to 8000 containers per hour

Production volume of 200 cc cups of tea is about 25,000 to 30,000 cups per hour

Production capacity of 300 or 400 cc juice glasses is about 14,000 to 16,000 pieces per hour

Required hall area:

According to the dimensions of the press machine for the production of thermoforming containers, which are 7 meters long, 2 meters wide and 2.5 meters high, so the desired hall should be at least 12 to 13 meters long and at least 7 to 8 meters wide.

But it is better to consider between 150 to 200 meters for the semi-forming model dish production machine, considering the necessary space for the produced dishes and the raw materials next to the machine and the packing table of the hall.

If we intend to export production containers or provide production containers to dairy and food industries, we need a health manufacturing license from the Food Supervision Office.

Of course, the accuracy and rigor that is in the products of the food industry is not in this production, and most of the goal of supervision and hygiene in the packaging and personal hygiene of the manpower of the collection ..

One of the requirements for obtaining this license is a sanitary hall, but according to the above contents, a hall with 2 meters of tiled walls and a concrete or mosaic floor is acceptable.

Power required to start disposable thermoforming utensils:

To set up a container production machine for semi-forming system and its peripherals such as air compressor and plastic milling machine, 3-phase 100 amp power is required (quality and brand of parts used in making the machine have a great impact on the machine’s power consumption and main power. Some thermoforming devices on the market that consume 100 amps use more than 130 amps when working)

The power consumption of the thermoforming press along with the sheet production machine is about 200 amps

Number of labor force: 2-3 simple labor force and 1 skilled labor force

For each production unit, regardless of the number of machines, a manpower is needed as the operator and technician of the machine. For each unit and factory, one person is familiar with repair and technical work and has the power of fast learning.

Of course, there is no need for special education and expertise to operate and control the device, and being technical is more effective

Also, according to what kind of utensils are produced in the machine, for each machine, 2 to 3 people need simple and unskilled labor because the production volume of utensils is different from the type.

Thermoforming production line has the ability to produce containers with PS polystyrene and PP polypropylene raw materials, which are characterized by PP containers that are glass, white, soft and unbreakable.

PP material is cheaper than all plastic raw materials.

Due to the fact that the raw materials for working with the thermoforming press must be purchased ready-made, so due to the fact that rolls and sheets are used in various industries, as a result, it has many manufacturers and there are no restrictions.

After the production of containers, sheet waste is also collected in factories that do not have a sheet production machine and sent to the factory that produces the roll at certain intervals, and then in that factory, the sheet waste is turned into sheets by mixing it with new raw materials.

Disposable container steps in the production line of thermoforming system

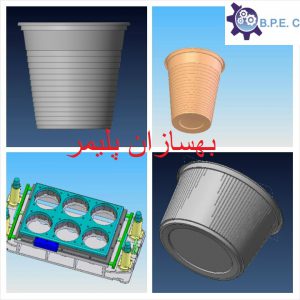

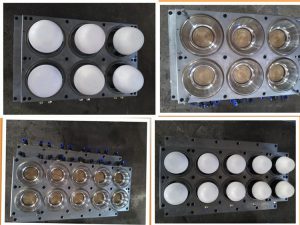

It is necessary to explain that all kinds of custom molds are designed and manufactured by the company itself and installed on machines.

Thermoforming container mold:

It is necessary to explain and note that among the manufacturers of the device in Iran, only 2 or 3 units have a license and exploitation license for industrial and mining structures, which Behsaz Polymer Industrial Group has been operating since 2000 under the exploitation license of the Industrial Organization.

And also, unfortunately, most advertisers on the Internet are intermediaries as manufacturers of disposable tableware and do not have any license from the Department of Industry and even choose the name of the company or brand to introduce their product is not registered in any office or organization.

Any copying of the contents of the site without including the source will be prosecuted.

We hope the above content was helpful

Behsaz Polymer Industrial Group