Rotary Joint

Rotary Joint

A rotary joint is a very practical piece that transmits liquids or gases by pressure. The most important application of a rotary joint is that it can remove the vapor-related fluid when the roll or roller is moving. This fluid is inside the roll on one side and contains steam or a cooled fluid on the other side.

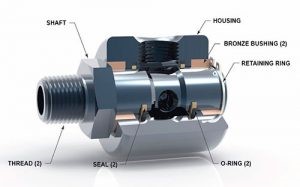

This product has 4 main bases which include sheath, shaft, bearing, station and other items and usually its steel and aluminum material is a better option against all kinds of pressure. The rotary sheaths are generally placed side by side and are a special entrance passage that makes a good supply level. This product is intended for rotating and expelling the liquid outwards, and in general, care should be taken when buying it.

Fluids used in rotary joints:

Fluids commonly used with rotary joints include heat transfer media and fluid force media such as:

- Steam

- Water

- hot oil

- Hydraulic fluid

- Air

- Coolers

They can also be configured for installation at the end of an axis or around an axis. The rotary shaft is designed to be placed inside the rotary and move. In buying, you should pay attention to the quality of this axis. In some devices, the axis acts as a sheath. The rotary core of a passageway is defined so as to prevent the fluid from falling out. This product generally has certain categories and can be implemented in the best conditions.

When buying this product, it is better to pay attention to the hinged joint. A revolving joint, also known as a rotating joint, establishes the correct connection between fixed tubes and rotating parts. Studies show that these joints cause the transfer of gaseous materials and eventually cause liquid or semi-solid to be transferred to the machines.

Design and construction

Rotary joints are made up of different parts and are categorized according to functional purposes and are elements that we can find in more or less any industrial environment. Including:

Plastic industries, pharmaceutical and chemical industries, paper and printing industries, food industries, automotive industries, steel, oil and gas processing…

They are elements used with a variety of fluids and in a very variable range of pressures. Also in different types of one input-one output, several inputs-multiple outputs are made. The material used in the design of these unions is chemically compatible and anti-leak. (Edited)Restore original

Increasing the use of rotary joints in industry is boosting the global rotary market.

There is currently a wide range of rotary joints on the market due to technological advances. Due to significant growth in many industrial sectors, including aerospace, energy, defense, plant automation, food and beverage, heavy equipment, oil and gas, medicine and metal, the rotary market is likely to expand gradually.

Rotary joints have different types and are designed very different in terms of raw material and construction position. Rotary joints are classified into single-port and multi-port models in terms of number of ports.

Rotary joints are designed in models of rotating joint, swivel joint and rotating knee, which in turn follow the flow of fluid from one tube to another. Rotating equipment generally forms a specific position.

There are rotary types for air, water and steam as well as hot oil and are sold in 1000, 2000, 3000, 4000 and more series. These products are considered in sizes of 1.8 and 72 and the maximum working pressure is estimated up to 1400 times.

The maximum operating temperature is estimated to be 315 ° C. The maximum speed for this case has been checked up to 3500 rpm.

Important information for choosing a joint rotary:

- Type of fluid (steam, water, air, etc.)

- Rotational speed

- Pressure

- Temperatures

- Flow rate

- Size of plumbing and equipment

Choosing a rotary joint is an important option that needs careful consideration. از برنامه های اختصاصی و تخصصی برنامه کاربردی گسترده برای ارزیابی ظرفیت جریان و افت فشار و همچنین برآورد عمر سیل در شرایط عملیاتی واقعی استفاده میشود.

The degree of accuracy of its mechanical elements is determined by the application that we can find and determine the amount of attention desired. They are elements with a common design, we will find stationary parts, rotating parts and one or two sealing elements.

Depending on the temperature affected during operation, it must be cooled by an external circuit through which the fluid passes through the rotary joint, which rotates again. Rotary joints are suitable for hydraulic pressure supply.

Types of Joint Routes

-

Rotary Joint Steel

Rotary joint steel is commonly used in large industries and is used for casting machines. The steel used for this style of rotary is very important and guarantees the working position.

Rotary steel is usually made of 304 stainless steel spool, so that a spring holder opening is also made of high quality steel. The spring used is made of spring steel and is not made of 302 stainless steel.

The door used is made of stainless steel and is not in the shape of a 304. A sealing gasket is applied between the door and the body. ذغال کربن ایتالیایی به کار رفته برای درب و زیر اسپول و همینطور برای پوسته نیز اجرا می شود.

-

Rotary oil joint

Rotary oil joint is for oil and gas industry. This product reduces operating costs and may increase safety optimization and, of course, lower the risk level. Rotary oil joint is usually an air-vapor transfer valve, as well as a water joint rotary list.

This valve is run hot and cold. The steel shaft used is stainless steel for this product. The maximum pressure is 10 bar and the maximum temperature is 315 ° C. Acceptable speed for this rotary is 250 rpm. These rotaries are on the list of filament and distribution joints and also have special washers for high temperature resistance.

-

Rotary Pneumatic Joint

Rotary pneumatic joint is a practical option for steam and water circulation that is related to mechanical equipment. This model of rotary generally includes high quality and will gain high confidence in the market.

These parts generally contain a number of complexities but are reasonably priced. The pneumatic rotary joint has a special shaft and a special motor so that it causes the required output power day.

It is necessary to explain and note that among the manufacturers of the device in Iran, only 2 or 3 units have a license and exploitation license for industrial and mining structures. Behsaz Polymer Industrial Group has been operating under the license of the Industrial Organization since 2000.

Thermoforming chain rails are made of special polymer material resistant to abrasion and heat and can also be produced alone with a metal cover base.

Any copying of the contents of the site without including the source will be prosecuted.

We hope thesa content was helpful

Behsaz Polymer Industrial Group