PET sheet production machine

This machine is completely different from PP.PS sheet production machines in terms of structure, accuracy and sensitivity in production

It is designed and manufactured in 3 main sizes of 80, 100 and 120 cm width in this company

Production sheet thickness: 0.1 – 1.8 mm

Width: 80, 100 and 120 cm

Production capacity: 400 and 600 kg / h

Complete PET sheet production line

Extruder sheet production machine

Extruder with two parallel helical extruders

With a helix diameter of 75 mm

L / D = 48

Length 360 cm

Capacity 400 Kg / h

The extruder has:

- Lattice with two filters and automatic switch hydraulic jack

- T-DIA head die width 900 mm, two blades with load slot

Technical information of the extruder part of the technical production machine

Screw Diameter 75 mm Mardon diameter

Screw Long 3600 mm Mardon length

Screw Ratio 48: 1 Mardon diameter to length ratio

Screw Rev.Speed 0 – 180 Rpm / Min Mardon speed range

Screw Barrel material 38CrMOALA Mardon cylinder material

Screw HeatingTreatment nickel vs chrome hardness thickness: 0.5-0.7 hardness

Barrel Heating Treatment Nitrogenized hardness> HV950, thickness: 0.5-0.7 Nitrate rate

Barrel Cooling Method Fan cooling system

Extroder motor Power 80 kw Electric cylinder power

Barel Heating Power 3kwx 6 Zones Number and consumption of cylinder energy

Screen Chenger Heating 3 kw Power consumption filter energy

Barrel Cooling Metod Cooling System Extruder

Fan cooling with water circulation around the element

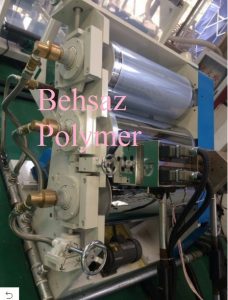

T-DIE head part and sheet machine cylinder

Specifications of T-DIE head and sheet machine calender

Max. Width Die Head 900 mm Maximum width of the die head

Min. Width Die Head 720-820 mm Sheet width minimum

Die Head Lip Thickness 0 – 2 mm Head blade thickness range

The Head Material VCN is the material of the head blade

Die Head Heating Power 3 kw * 6 Zones T_DIE Number and energy consumption

Cylinder specifications of the device

Cylinder Roller Width 900mm

Roller width

Cylinder Roller Diameter 500 mm Roller diameter

Cylinder Roller Material CK45-60 Roller material

Cylinder Roller Colling Oil & Water Type of roller cooling

Overall Dimension (m): 13 / 1.8 / 2.2 Dimensions of sheet metal

All Power 380/3 / 50hz / 54kw Total power consumption of the device

Weight: About 6.5T Overall weight

Winder part of sheet production machine

Summary of information

Extruder:

Cylinder and Mardon The extruder part is a two-screw type made in Taiwan and has a segmented cylinder and a segmented screw.

The cylinder ratio is 1 to 48 and the helix diameter for the 400 kg model is 75 mm

With the agreement of the buyer, the elements are equipped with a fan or water cooler

Cylinder device:

The next device is the Cylinder system, which is designed with three super-polished rollers with a diameter of 500 mm at an angle of 45 degrees. The driving force of the rollers is each supplied separately by the servomotor and the gearbox with helical gears and has a very easy ability to adjust the film thickness between the rollers.

Device (Cross Winder):

Two-jaw plate collector that has the ability to replace the sheet ball without stopping the line. The jaw-changing mechanism is designed with a gearbox motor and the drive shaft (Air shaft) is a collector with a hydraulic mechanism.

Millet pump:

If ordered, the pump pump will be added to the extruder and its brand and material will be determined by agreement with the buyer.

List of brand parts used in the manufacture of PET sheet line

It is necessary to explain that more than 80% of electrical parts and technical accessories, with reputable European brands in the market, are not original and are made under license with European names in China or Czechoslovakia and Romania, but the accessories and parts used in this Due to the sensitivity of the production, the device is made in Europe and the price of the device is calculated and announced based on the use of parts with the brand mentioned in the manufacture of the device.

Mardon cylinder: – Taiwanese 5-year warranty

Electromotor: MARELLI – SIEMENS Germany – MOTOVARIO Italy AEG – ABB

PLC and HMI Inverter: Siemens (SIEMENS) – ABB Telemechanics (Schneider) Siemens and ABB – Italy – OMRON Japan –

Panel electrical components: Legrand France – French telemechanics (Schneider electric) – Siemens (SIEMENS) Germany

Hydraulic Pneumatics: CAMOZZI Camus Italy – Italy – Parker François Germany – Festo Festo Germany

It is necessary to explain and note that among the manufacturers of the device in Iran, only 2 or 3 units have a license and exploitation license for industrial and mining structures, which Behsaz Polymer Industrial Group has been operating since 2000 under the exploitation license of the Industrial Organization.

And also, unfortunately, most advertisers on the Internet are intermediaries as manufacturers of disposable tableware and do not have any license from the Department of Industry and even choose the name of the company or brand to introduce their product is not registered in any office or organization.

Any copying of the contents of the site without including the source will be prosecuted.

We hope the above content was helpful

Behsaz Polymer Industrial Group